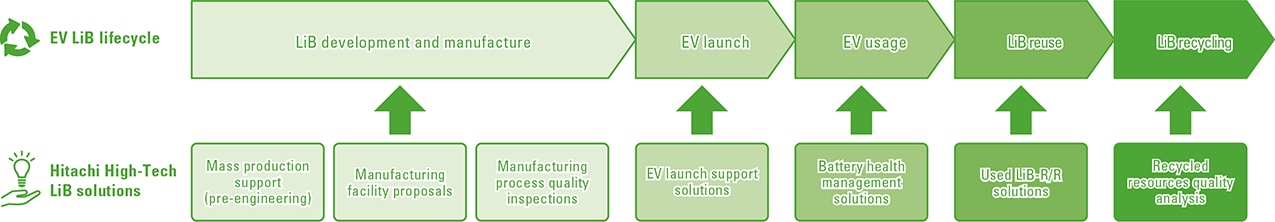

Contributing to the resolution of lithium-ion battery (LiB) issues, from initial development to final reuse

Developing solution supporting the accelerating shift to EVs

To counter global warming, the automobile industry is accelerating the shift from gasoline and diesel to electric vehicles (EV). We propose LiB*1 manufacturing facilities essential for EVs, and provide development and production support to manufacturers of next-generation batteries (advanced LiB*2, all-solid-state batteries*3, etc.). We also provide inspection solutions to ensure battery manufacturers produce safe LiBs.

Furthermore, we aim to develop solutions that cover the entire LiB lifecycle, from decisions regarding EV launches, optimal EV operation and maintenance, and extending LiB lifespans, to their reuse and recycling.

*1 Lithium-ion batteries (LiB): Considered to be relatively environmentally friendly, as they do not use lead, cadmium, or other harmful substances. Recycling technologies are also advancing, making it is possible to extract resources from used batteries.

*2 Advanced LiB: Next-generation secondary batteries based on existing LiBs that offer improved performance.

*3 All-solid-state batteries (all-solid-state lithium-ion secondary batteries): Batteries with solid rather than liquid electrolytes, which improves safety and reduces the risk of fire. As they are also capable of rapid charging, they are expected to be used in electric and other vehicles.

Pre-engineering activities supporting the development and manufacture of next-generation batteries

LiBs used in EVs at present are expected to account for more than 60% of the mobility battery market by 2030. At the same time, the development of next-generation batteries with reduced environmental impact and higher performance is also accelerating, and research and development is progressing around the world aimed at practical application and mass production. Hitachi High-Tech dispatches engineers to manufacturers that have recently entered the next-generation battery manufacturing industry, and our expanded manufacturer support, from the development of prototype lines to the development of equipment for mass production, facilitates the realization of prototype and pilot production. We will continue to support advanced battery development and accelerate efforts to quickly realize a decarbonized society.

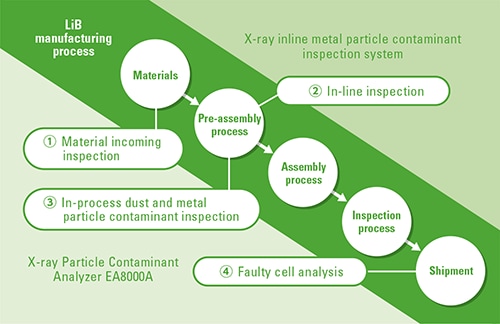

Protecting the quality and safety of LiBs with inspection solutions that instantly detect contaminants

LiB safety and quality requirements are becoming increasingly stringent. If metal fragments or other contaminants are allowed into the LiB manufacturing process, even if they are microscopic, they can affect quality, including reducing battery life. Furthermore, LiBs that include contaminants may overheat or even ignite, which could lead to vehicle fire or cause personal injury. Hitachi High-Tech provides inspection solutions that detect contaminants at LiB manufacturing sites. In FY2023, we introduced and began verification of X-ray Particle Contaminant Analyzer EA8000A used for sampling inspections, as well as the X-ray inline metal particle contaminant inspection system, a new contaminant inspection solution for 100% inspections.

Introducing particle contaminant inspection systems on production lines (in-line) facilitates the visualization of the extent to which contaminants are generated in the manufacturing process, which is useful for reducing defect rates. Additionally, contaminants can be removed from the manufacturing process at an early stage, contributing to lower material costs. In FY2024, we will repeatedly engage in discussions with customers and promote efforts aimed at reducing contaminated product disposal costs, and begin considering inspection solutions for next-generation batteries.

Going forward, we aim to develop services utilizing artificial intelligence (AI) to further improve manufacturing efficiency and reduce material waste, as well as to predict and prevent particle contamination before it occurs. We will continue to contribute to the global environment and the development of science and industry through innovations that support LiB production lines.

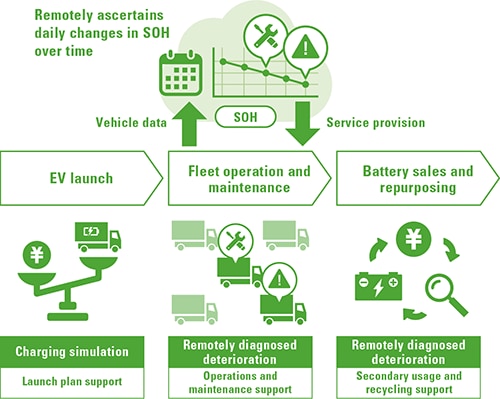

Total resolution of LiB lifecycle issues

Across a wide range of industries, there are high expectations for the expansion of electrification in commercial EVs, buses, construction machinery, agricultural machinery, ships, and railways. At the same time, the introduction of EVs requires considerations and operations that differ from those related to internal combustion engine vehicles in terms of cost, operational efficiencies, and regulatory compliance. Accordingly, we developed technologies to remotely diagnose LiB deterioration based on issues faced by fleet operators*4. By continuously estimating battery state of health (SOH) and optimally timing operation and maintenance accordingly, we are able to streamline operation and maintenance, while also minimizing LiB deterioration and achieving longer lifespans. In addition, after the end of their useful life in EVs, automotive LiBs are expected to be used for other purposes. Managing and visualizing changes in SOH over time along with operational history data starting from when the LiB was installed in the vehicle facilitates the appropriate use of LiBs for secondary applications and recycling. In FY2023, we collaborated with a major commercial EV rental company and confirmed the feasibility of estimating LiB degradation remotely with a high degree of precision, as well as the potential for providing value such as extending battery life through remote SOH diagnoses.

Reducing CO2 emissions through electrification also leads to the quantification and distribution of environmental values, such as the certification and trading of emission rights and carbon credits. Additionally, EVs have their own unique issues, such as insurance premiums, financing, and resale value, and the utilization of vehicle and battery operation data will help resolve these issues as well. Going forward, we will collaborate with a variety of companies to create LiB lifecycle management solutions that resolve battery lifecycle issues, such as promoting secondary applications for used LiBs and maximizing their lifetime value, with the aim of further expanding economic and environmental value.

*4 Transportation, bus, taxi, rental car, and leasing companies as well as and other businesses that operate a large number of vehicles for the purpose of moving people and goods.