The challenge of going plastic-free: Changing transport packaging materials

The transition to plastic free

Plastics emit large amounts of CO2 during their manufacturing process and incineration. And left disposed in nature, they can cause soil and marine pollution. The movement toward plastic-free is currently accelerating worldwide. The EU adopted the Single-Use Plastics Directive in 2019, which regulates plastic tableware, straws, and containers. In addition, policy to tax non-recyclable plastics was set in 2021, and many member countries are moving in the direction of taxation. In response to this trend, the plastic cushioning material that has been used for many years for shipping spare parts for biochemical and immunoanalyzers to our partners has been replaced with recyclable recycled paper cushioning material.

Changing to environmentally conscious cushioning material while maintaining shipping quality

When shipping spare parts to our partners, we formerly used multiple layers of plastic cushioning material to protect the products from external shocks during transportation and maintain the quality of shipping. Meanwhile, using plastic cushioning materials in large quantities as the accelerating trend toward phasing out plastics made plastic waste an issue for partner companies and motivated us to reconsider the cushioning materials we use.

During this review, we set policies to reduce the volume of materials used, change to environmentally friendly cushioning materials, and review packaging methods. Specifically, Hitachi High-Tech has adopted the principle of collective packaging, in which multiple types of spare parts are packed together. When extra space is available in the outer box, the amount of cushioning material required has been greatly reduced by trimming the outer box down to match the item to be delivered. Even though the cost of recycled paper cushioning material itself is more expensive than plastic cushioning material, we were able to change to recycled paper cushioning material at no additional cost. We have also conducted impact tests and tested actual transportation routes with the cooperation of our partners to ensure that there are no issues with shipping quality.

Reduction impact by changing cushioning material

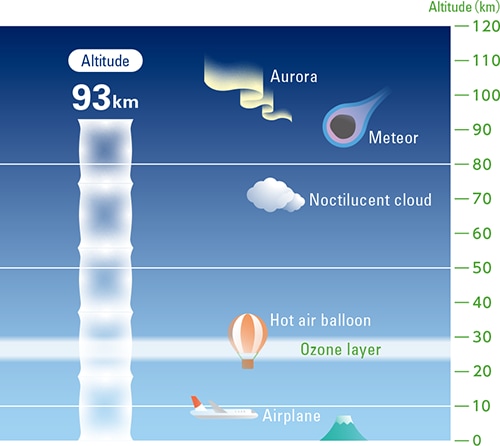

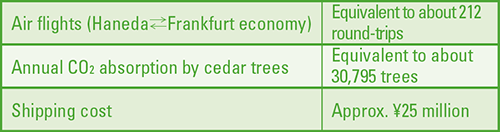

As a result of reviewing packing methods and switching to recycled paper cushioning materials, in FY2023 we reduced the length of plastic cushioning materials by approximately 93 km, equivalent to 271 tons of CO2 emissions during air shipping. In addition, shipping costs were reduced by the equivalent of approximately ¥25 million. Moreover, our partners are reusing the recycled paper cushioning materials sent from us as new packaging, leading to further reductions in packaging materials. We will continue to actively engage in methods that are unbound by conventional methods to lessen our environmental impact.

Reduced length of plastic cushioning

Effect of reducing CO2 (271t)