Using temperature-sensing QR code labels to build a cold chain for amberjack exports

Aiming to establish a cold chain under optimal conditions for the transportation of amberjacks

In Japan, primary industries are declining due to the aging of the population and lack of successors, and consumption is also declining due to a shrinking population. Meanwhile, exports of agricultural, forestry, and marine products and foodstuffs to overseas markets are on the rise, partly due to the recent explosion in the popularity of Japanese food. To deliver delicious Japanese products, it is essential to have a well-developed cold chain that can guarantee safety and quality. The food distribution supply chain must also address issues such as the disposal of plastics and reduction of CO2 emissions in consideration of environmental impacts. In collaboration with the Tarumizu City Fishermen’s Cooperative (Kagoshima Prefecture) and Kizasu Co., Ltd., we conducted a demonstration test to expand exports of amberjacks produced in Kagoshima Prefecture, improve added value, and maintain freshness.

Maintaining quality during transportation and optimizing excessive use of ice packs

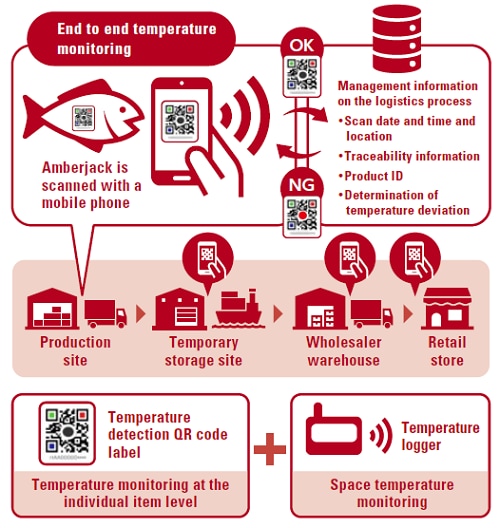

Hitachi High-Tech participated in a demonstration test aimed at maintaining freshness to increase the added value of amberjacks using the MiWAKERU® temperature control service, which incorporates the use of temperature-sensing QR code labels developed by Hitachi, Ltd., and Hitachi Solutions, Ltd. Normally, the spatial temperature inside containers and product cases is monitored during transportation, but in this demonstration, temperature-sensing QR code labels with ink that changes color when the temperature changes were attached directly to products (amberjacks) to detect temperature. This resulted in realizing comprehensive temperature monitoring, both of individual items and entire cases of products. By visualizing product quality based on temperature changes during the transportation of amberjacks farmed in Japan and shipped to overseas restaurants, we verified the potential for reducing transportation costs, waste, and CO2 emissions. In conducting this demonstration, we were also able to reduce the amount of ice packs used in product cases. By optimizing the amount of ice packs used, we were able to reduce shipping weight and costs, as well as contribute to the reduction of CO2 emissions during transportation.

MiWAKERU® temperature control service

Aiming to support temperature control in a wide range of fields, including agriculture, forestry, fisheries, and pharmaceuticals

For producers, serving amberjacks of inferior quality due to poor temperature control results in a loss of trust from local restaurants and other customers.

With MiWAKERU®, temperature control information is automatically recorded by reading temperature-sensing QR code labels attached to individual products using a dedicated smartphone app. Temperature control information compiled on a server can be confirmed at various touch points during transportation. Going forward, we will contribute to protecting the value of domestically produced products and improve their brand power through support for the creation of optimized cold chains for amberjacks, as well as other agricultural, forestry, and fishery products.

In addition to agricultural, forestry, and fishery products, we will also consider the utilization of temperature controls on an individual product basis for pharmaceuticals, chemicals, processed foods, and other products requiring temperature control. In this way, we will continue to contribute healthy, safe, and secure lives.

QR code labels on an amberjack

* QR Code is a registered trademark of DENSO WAVE INCORPORATED.