Initiatives for SX in supply chain management

SX initiatives through building a common digital infrastructure with procurement partners

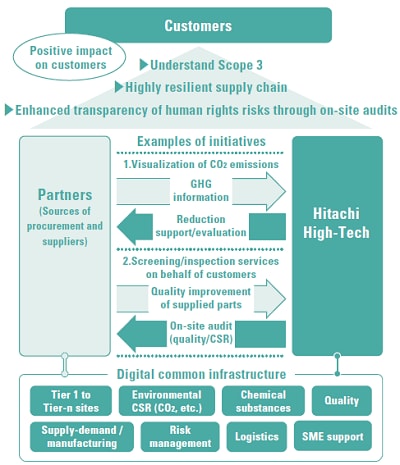

Companies are required to strengthen their supply chain resilience and sustainable management to flexibly respond to supply chain disruption risks caused by pandemics and geopolitical factors and to social issues such as human rights and the environment. For its part, Hitachi High-Tech is building a common digital infrastructure with its procurement partners.

By visualizing various data and sharing information in a timely manner, it is possible to identify problematic areas, make advance forecasts, and understand CO2 emission volumes. Specifically, procurement partners can equalize workloads and accurately plan production by visualizing the scheduled delivery dates of a wide variety of parts. We also conduct quality and acceptance audits for procurement partners with the aim of visualizing quality data. Furthermore, by acquiring the CO2 emission volumes of procurement partners, it is possible to understand the CO2 emissions in our own value chain and provide more accurate CO2 emissions data to customers in response to social demands.

Building a common digital infrastructure

To improve the quality control and reduce CO2 emissions of procurement partnersa

By collaborating with TRIGO, one of the world’s leading providers of advanced quality services, Hitachi High-Tech is progressively improving the efficiency of its procurement partners’ site inspections, quality reviews, and acceptance inspections. In FY2023, we deepened our collaboration and conducted not only conventional quality control audits but also chemical substance control audits at some of our procurement partners. Furthermore, by supporting improvements through checking work procedures and manufacturing processes, we helped our procurement partners improve their manufacturing process yields.

The Hitachi High-Tech Group’s goal is to achieve carbon neutrality throughout its value chain by FY2050 and to reduce carbon emissions by 50% by FY2030. To achieve our goals, we need to cooperate with our procurement partners to reduce CO2 emissions. In FY2023, we began operating a GHG calculation tool that enables the collection and aggregation of corporate per-unit CO2 emissions for our product procurement partners. By streamlining the collection of CO2 emissions, we reduce the burden on our procurement partners and the Company in terms of aggregating CO2 emissions.

Furthermore, we conducted an analysis of the CO2 emission reduction plans and measures of the environmentally advanced partners selected from among our procurement partners. Based on the results of the analysis, we will work together to further reduce CO2 emissions.

Image of front-line confirmation by a procurement partner

Aiming to build a sustainable supply chain

Aiming to provide proxy audit and inspection services its customers, Hitachi High-Tech is first advancing the use of quality data within its supply chain to improve the quality of its procured goods and enhance the audit and inspection processes of its procurement partners. The Company visualizes defect reports from procurement partners, accumulated data of internally received and in-process defects, results of TRIGO screenings, and consultation and inspection data. We aim to develop tools for on-time visualization and analysis to quickly resolve issues and reduce administrative processes.

In Europe, the need for onsite ESG assessments conducted at suppliers’ sites as an element of risk management is also expanding, especially among automakers. Hitachi High-Tech is also looking into conducting ESG assessments in conjunction with quality audits. Conducting these simultaneously with quality audits will also help reduce the burden on procurement partners.

Regarding the emission volumes of procurement partners, we will further apply GHG calculation tools that collect and aggregate emissions and aim to commercialize them and provide them to customers. In FY2023, we had developed tools for each company, and in FY2024, we aim to complete the development of a GHG calculation tool for each component. We will continue our efforts to achieve carbon neutrality throughout our value chain, including Category 1 of Scope 3.