Sustainability

Lately, climate change has become an international issue. To help solve this issue, we must shift away from fossil fuels toward electric energy. Batteries are an essential device for this shift, so the need for them is growing around the world.

The automotive field is also rapidly shifting from gasoline and diesel to electric vehicles (EVs) and fuel cell vehicles (FCVs), and so the demand for automotive batteries is also rising.

Key to the safety and quality of these batteries is preventing metal particle contaminant from entering the manufacturing process. No matter how small the metal particle is, any contamination can cause not only quality deterioration but also fire and other accidents.

Hitachi High-Tech provides inspection solutions for battery manufacturing sites by utilizing X-ray technologies developed in the industrial field. Fine metal particle contaminant is instantly detected, and the type and source of the matter are identified.

By supporting manufacturing sites and helping popularize EVs in this way, Hitachi High-Tech contributes to a sustainable global environment as well as further technological innovation in high-capacity, high-output batteries.

Climate change is manifesting itself in visible ways such as heatwaves, typhoons, wildfires, droughts and localized downpours, causing a variety of impacts and damage to the natural environment and people's lives. In 2023, the average temperatures in Japan and the world reached record highs, and an immediate response is needed.

The Paris Agreement was adopted at an international conference on climate change in 2015. Aiming to prevent future crisis, countries agreed to keep the global average temperature increase to well below 2°C pre-industrial levels, and work to limit the temperature increase to 1.5°C above pre-industrial levels.

To achieve this, it is important to drastically reduce CO2 and other greenhouse gases, and it is necessary to move away from a society that relies on fossil fuels (coal, oil and natural gas).

In the transportation and traffic sector, a shift to electric vehicles that reduce CO2 emissions during travel is a pressing issue. The International Energy Agency (IEA), an international advisory body of which Japan is also a member, states that measures such as electrification of 60% of global vehicle sales by 2030 are necessary.

There are currently three main types of electric vehicles:

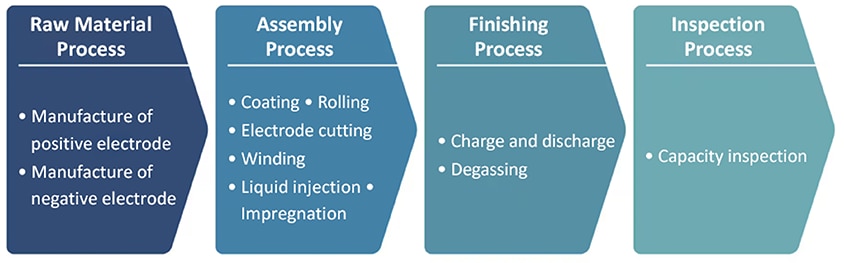

There are multiple types of electric vehicles, but the one device that is essential in all of them is the battery that stores the electricity. For typical lithium-ion batteries, the manufacturing process is roughly divided into four parts.

The first process is the raw material process. Battery electrodes consist of a positive electrode and a negative electrode. Cobalt and nickel are used for the positive electrode, and the negative electrode is mainly made from carbon materials. In the raw material process, these raw materials are mixed together to create electrodes.

Then comes the assembling process, in which the electrodes are cut and rolled with a roller; the finishing process, which consists of charging/discharging and degassing; and the inspection process, in which the capacity and performance of the finished battery are inspected before being shipped as a product.

The key to producing high-quality batteries is preventing metal particle contamination. Various measures have been taken by battery manufacturers, but even when taking the utmost care it is difficult to eliminate contamination by fine metal particles generated in the manufacturing process.

Hitachi High-Tech provides X-ray metal particle contaminant inspection and analysis solutions focused on automotive batteries. By implementing these solutions, contamination can be detected at an early stage along with the source of any identified metal particle contaminant, leading to process improvements.

Masaaki Muraoka, Manager of the Hitachi High-Tech Science XR Sales Dept., explains the importance of this technology.

"Metal particle contamination not only leads to quality issues such as a reduced battery life, but also carries the risk of overheating and ignition. When used for automobiles, contaminated batteries can lead to fatal accidents, and we must make sure that we can reliably detect metal particle contaminant and take countermeasures."

Hitachi High-Tech launched the X-ray particle contaminant analyzer for automotive batteries in 2013. It was just around the time when manufacturers in Japan were starting to launch electric vehicles. Muraoka recalls,

"It all started when I was consulted by a battery manufacturer about the possibility of metal particle inspection using X-rays. We already had general-purpose defect inspection tools, but we didn't have anything specialized for automobile batteries. At that time, it took about 10 hours to detect and analyze metal particle contaminant."

In addition to high-precision inspection and analysis, speed is also necessary at mass production sites. Hitachi High-Tech has been making improvements at the request of manufacturers, and now fine metal particle contaminant in the range of 250 × 200 mm can be detected in a few minutes to 10 minutes. The nature of metal particle contaminant detected can also be identified during the process.

Hitachi High-Tech currently provides two types of solutions.

Muraoka explains the role each system plays:

"Spot-checks are performed by (1), where a part of the lot is extracted from the production line as samples for inspection. From there, metal particle contaminant and their sources can be further identified, which are connected to yield and reduced defect rates. In contrast, the 100% inspection performed by (2) inspects all lots flowing on the production line with no exceptions, and checks for metal particle contaminant in real time."

The EA8000A, which can perform both metal particle contaminant detection and elemental identification, has both the functions of the eyes and brain. On the other hand, the groundbreaking feature of the in-line inspection system is the ability to perform 100% inspection with its specialized eye-like functions.

In this way, the two solutions play different roles and complement each other. The key technology in both systems is X-rays that can detect metal particle contaminant buried in opaque objects.

X-rays used in the medical field or for baggage inspection at airports may come to mind when you hear the term. In addition to these applications, Hitachi High-Tech has been providing X-ray-based solutions in the industrial field over the years.

Toshiyuki Takahara, Senior Engineer in Analytical Instruments System Design Dept., of Hitachi High-Tech Science, explains the core technologies that combine high-precision inspection and speed.

"As an example, we needed to increase the sensitivity of X-ray cameras in the in-line inspection system to cope with the speed of the customer's production line, and to develop image processing software that corresponds to that increase. We have improved accuracy through these technological developments, which enabled us to provide solutions for detecting micro-level metal particle contaminant."

A joint project with an automobile manufacturer marked the turning point in the development of X-ray metal particle contaminant inspection and analysis solutions for automotive batteries. Takahara recalls,

"We were required to develop solutions to inspect for metal particle contaminant as small as a few tens of micrometers in each cell on the fuel cell manufacturing line for passenger cars in a matter of seconds."

A cell is a flat cell that generates electricity through chemical reaction between hydrogen and oxygen. Fuel cells for passenger cars are structured in layers. Takahara continues,

"Each vehicle used 330 cells in this project. Also, because of the high production volume, we needed the unprecedented speed of just a few seconds per cell for 100% inspection.

In order to meet these requirements, the automobile manufacturer, equipment manufacturer and Hitachi High-Tech began working on development together. In particular, the defect inspection tools incorporated in the production line must achieve both the high quality and safety demanded by the automobile manufacturer, so cooperation with the equipment manufacturer was indispensable.

In this way, by combining each other's technologies and knowledge and repeating prototyping and verification, the required level was reached in about six months' time, ahead of the original 10-month schedule.

In addition to the inspection speed, accuracy improvement was also an important topic.

Fuel cells need to be as thin as possible per cell in order to increase the power generation efficiency per volume. However, the thinner the cell is, the greater the impact of metal particle contamination. Furthermore, the overall quality could deteriorate even if only one out of the 330 cells was contaminated with metal particle contaminant, so extremely strict accuracy was required.

"In order to meet this requirement, we worked to improve X-ray cameras so that they could handle higher speeds and higher accuracy. 'Necessity is the mother of invention' was true. The experience gained through this fuel cell project is also beginning to play an active role in lithium-ion battery manufacturing," said Takahara.

Lithium-ion batteries have become mainstream for battery electric vehicles (BEVs), and demand for them is growing worldwide. As the market expands and mass production increases, the speed of inspection needs to advance even further.

Looking ahead to the future, Takahara says,

"In order to extend the range of EVs, the capacity and performance of batteries is rapidly increasing. As a result, the demand for faster and more accurate inspections will also increase. We would like to continue to help solve customer and social issues by making full use of Hitachi High-Tech's core technologies."

Hitachi High-Tech Group has formulated five materialities (key topics) for solving social issues, based on SDGs (sustainable development goals).

X-ray metal particle contaminant inspection and analysis solutions contribute to "1) Contributing to a sustainable global environment" by supporting battery manufacturing sites, and "3) Contributing to the sustained development of science and industry" through innovation.

In terms of outlook for the future, Muraoka says,

"The utilization of data, which Hitachi High-Tech excels at, will also be an important topic. For example, AI (artificial intelligence) can be used to further analyze the inspected and analyzed data to identify trends in when and what metal particle contaminant is mixed in. Based on this, there is a good possibility that we can provide services that predict and prevent contamination in advance."

Automobiles, which became popular in the 20th century, made our lives more comfortable and gave us freedom and joy of movement. On the other hand, greenhouse gases emitted by the vehicles have contributed to climate change. Now, a new outlook on the shift to EVs is opening up. Hitachi High-Tech will support battery manufacturing sites as part of its role in creating a sustainable future.