Recycling of Resources

Basic Approach

Hitachi High-Tech Group is aspiring to create a resource efficient society, as part of our efforts for a 50% or greater improvement in efficiency of resource use compared to the base year, by FY2050 and our final goal of zero emissions (less than 0.5% of volume of waste generated) through reduction based on environmentally conscious design for in-house products, recycling with carefully sorted collection, and reuse of unused goods.

Independent Assurance

In order to enhance the credibility of this report, FY2023 figures marked with ![]() have received independent assurance from SOCOTEC Certification Japan Co., Ltd. in accordance with the International Standard on Assurance Engagements (ISAE) 3000 and ISO14064-3.

have received independent assurance from SOCOTEC Certification Japan Co., Ltd. in accordance with the International Standard on Assurance Engagements (ISAE) 3000 and ISO14064-3.

Initiatives

Reduction in the Volume of Waste Generated / Higher Rate of Reuse of Resources

The Hitachi High-Tech Group strives to reduce the volume of waste generated by its business activities and to promote recycling of resources by maximizing the recovery of resources from generated waste. Specifically, we are promoting efforts to optimize the production of products and parts by understanding supply and demand, paperless design, reduction of packaging material use, reduction of defective products through quality improvement, and reduction of chemical substances, while sharing examples of such measures among divisions. In addition, we are reducing waste generated by operating a business for the reuse of the etching equipment and electron microscopes we sell.

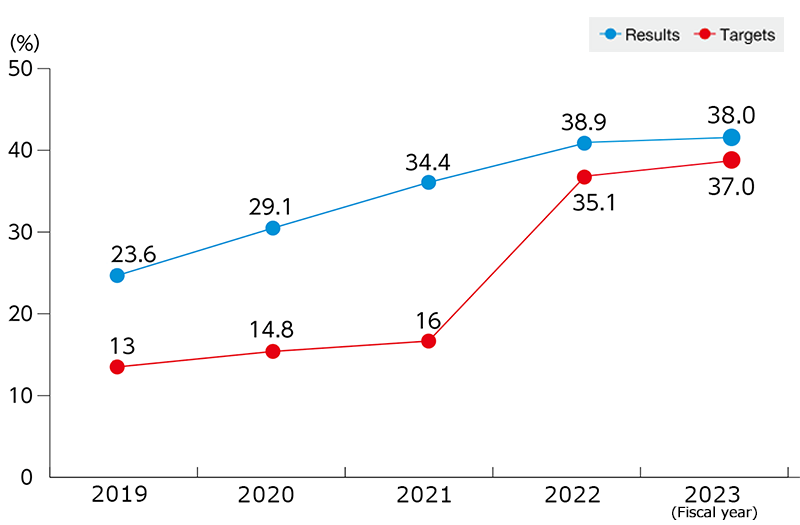

In FY2023 activities seeking to improve the volume of waste generated per unit by 37.0% (base year: FY2010) realized an improvement of 38.0%, meeting the target.

We use a proprietary Hitachi High-Tech Group tool to centrally manage the volumes of hazardous waste generated and exported for each category and ensure strict compliance with relevant laws and regulations, including the proper use of industrial waste management forms (manifests), and proper disposal within the Group. We also encourage proper disposal by including safety precautions for disposal in the instruction manuals of the products we sell.

Resource Recycling Initiatives of the Hitachi High-Tech Group

At each stage of the product lifecycle, the entire Group implements initiatives that we can undertake as Hitachi High-Tech Group. We pay close attention to even the smallest details in the manufacturing stage of our products, believing that many small efforts together become a great strength.

Performance Data

Changes in Volume of Waste Generated in Japan –Improvement Rate per Unit

* Reporting boundary: Hitachi High-Tech (excluding branches), Group manufacturing companies and service companies in Japan

* Energy usage improvement rate per unit: The rate of improvement over the base {(1 - base units of the relevant site for the relevant fiscal year/base units of the relevant site for the base year) × environmental impact at the relevant site for the base year calculated by group companies in Japan}

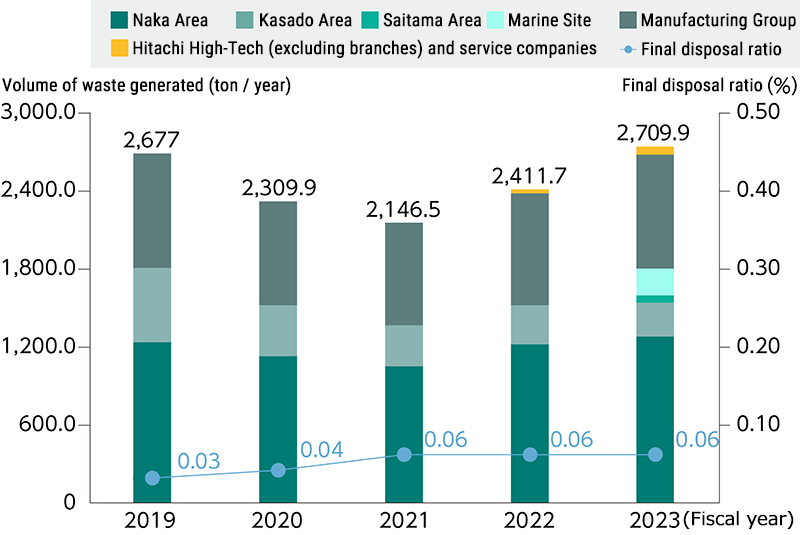

Changes in Volume of Waste Generated and Final Disposal Ratio in Japan

* Reporting boundary: Since FY2022, Hitachi High-Tech (excluding branches), Group manufacturing companies and service companies in Japan.

* Figures include waste, including valuable resources, generated from manufacturing activities

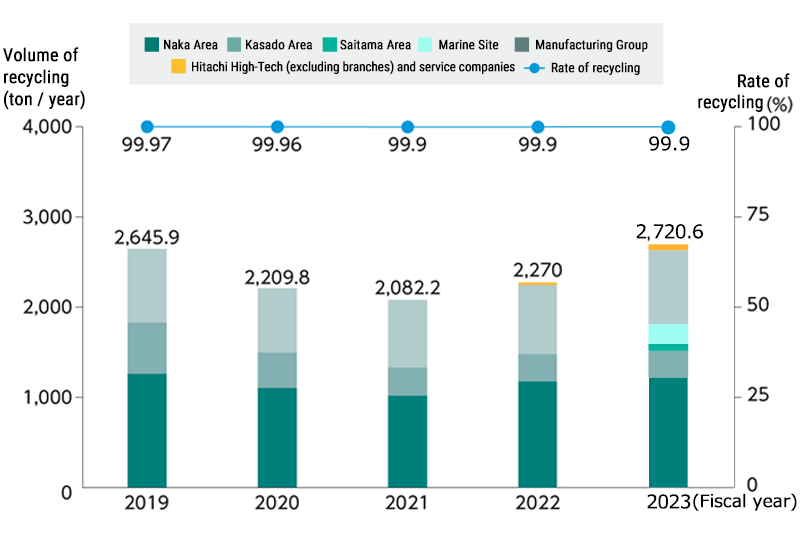

Changes in Volume of Waste Recycled and Rate of Reuse of Resources in Japan

* Reporting boundary: Hitachi High-Tech (excluding branches), Group manufacturing companies (excluding Tokyo Solution Lab) and service companies in Japan.

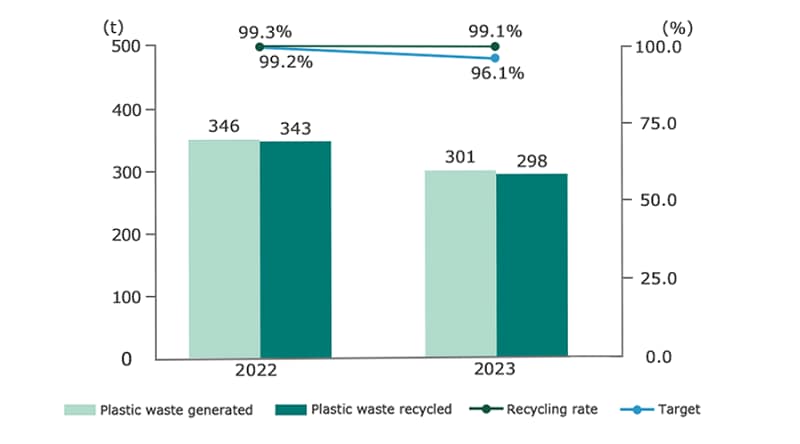

Volume and Percentage of Plastic Recycled

Disclosure based on the Plastic Resource Circulation Act

* Reporting boundary: Hitachi High-Tech's main production sites and offices

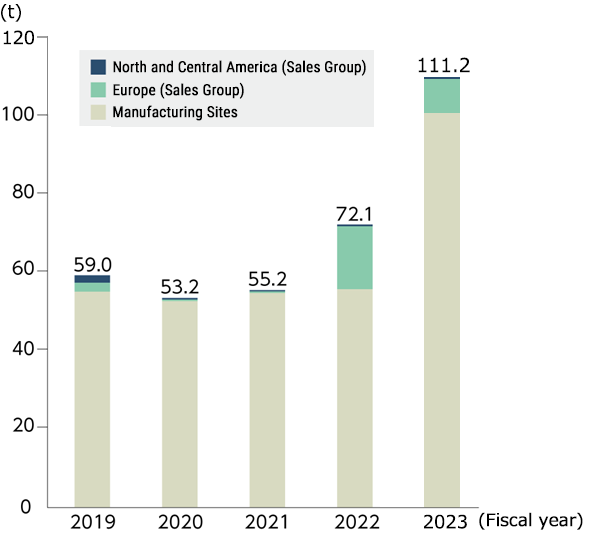

Changes in Amount of Waste Generated (Outside Japan)

As to the volume of waste generated at overseas subsidiaries, since FY2017 we have only been tracking hazardous wastes that are regulated in the country concerned. Going forward, we will consider activities to reduce those wastes.

* Reporting boundary: Overseas subsidiaries (Figures are for overseas Group manufacturing companies only. Hitachi High-Tech Analytical Science was newly included in the boundary from FY2018)

Promoting the Recycling of Used Packaging Materials

As part of our efforts to achieve a recycling-based society, our Naka Area is actively engaged in the recycling of waste within Japan. Vinyl used in the packaging of components delivered to us is used to manufacture polyethylene garbage bags and plastic folders made entirely from this recycled material, which are then used by the Naka Area. Seeing vinyl materials separated from other waste in the workplace come back to be used again in a different form makes the concept of recycling more tangible for staff, thereby helping to increase the environmental awareness of each and every employee. Going forward, we will continue to strive to reduce waste by expanding the scope of items subject to recycling and promoting the reuse and recycling of materials used to package components.