Polarized Zeeman Atomic Absorption Spectrophotometer ZA4000 Series

Taking Hitachi Atomic Absorption Spectrophotometers into a Next Stage

Hitachi offers high-precision background correction and high-sensitivity measurement by employing the polarized Zeeman correction method alongside the dual detector method.

The addition of a new rapid sequential mode* (supports the flame method) makes it possible to perform even higher throughput analysis, allowing for fast, precise, and highly reproducible measurements in a variety of fi elds, including research and quality management.

* A mode that sequentially analyzes multiple elements

Features

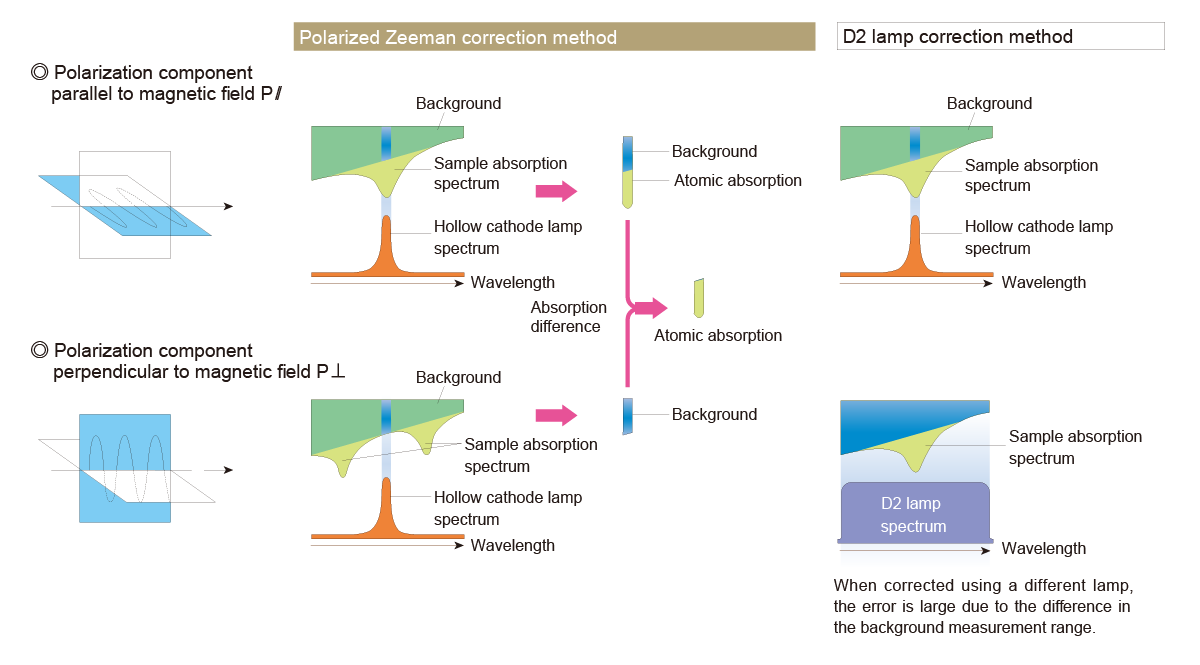

Polarized Zeeman Correction Method

Background Correction Using Only Hollow Cathode Lamp

The polarized Zeeman correction method, which uses a permanent magnet, provides a stabilized baseline, suppresses the effects of coexisting materials that have absorption of adjacent wavelengths, and facilitates highly reliable analysis.

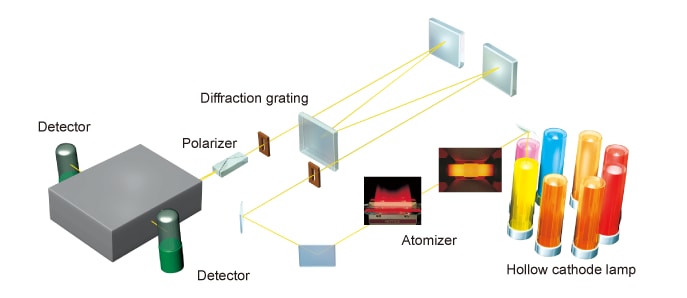

Dual Detector Method

Increases the Amount of Sampled Light and Reduces Noise

The dual detector method, by which the sample light and reference light are sampled by independent detectors, reduces the baseline noise. The two lights are also detected simultaneously, which increases the accuracy of corrections.

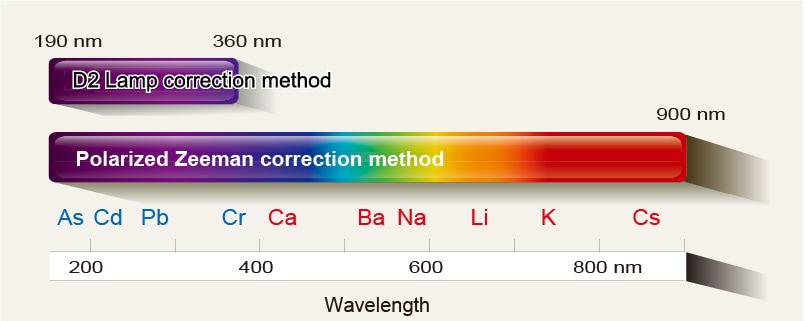

Wide Background Detection Range

All Elements are Covered by the Polarized Zeeman Correction Method

Background correction can be performed for elements that have absorption in the ultraviolet range or visible range. The polarized Zeeman correction method is one choice of correction method and has the advantage that it does not need to be selected for each element. It can also correct elements that cannot be corrected by the D2 lamp correction method, such as sodium and potassium.

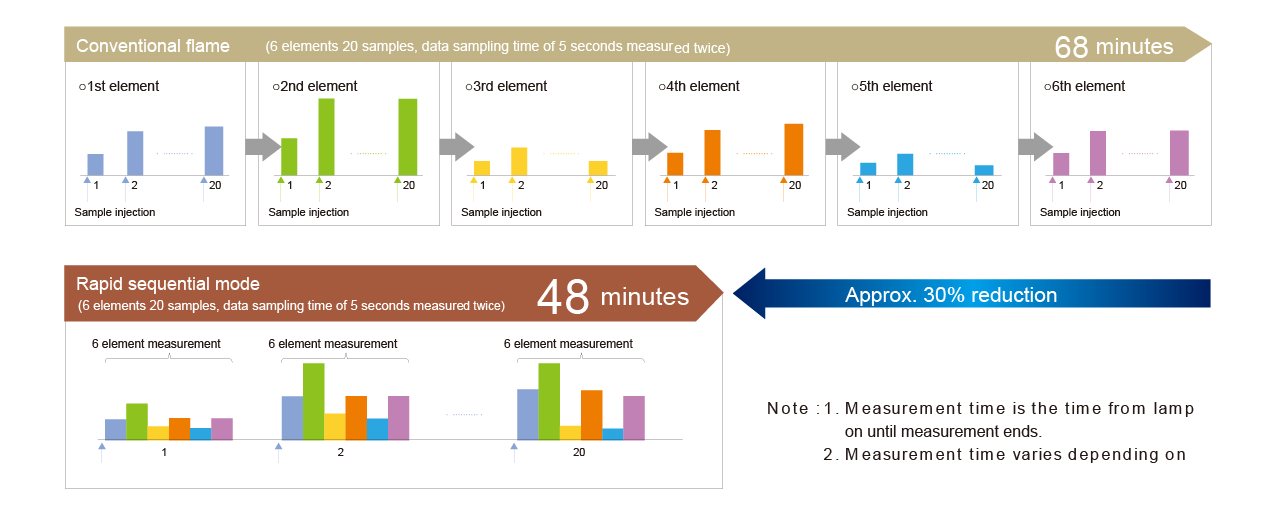

High-Accuracy, High-Speed Measurement by Rapid Sequential Mode(ZA4800)

Offering Sequential Measurement of a Maximum of 12 Elements and Faster Speed

Hitachi has achieved even higher speed in measurements by combining the existing polarized Zeeman correction method with a newly developed diff raction grating drive mechanism. This provides much faster measurements for users who are measuring multiple elements in the same sample using the fl ame method.

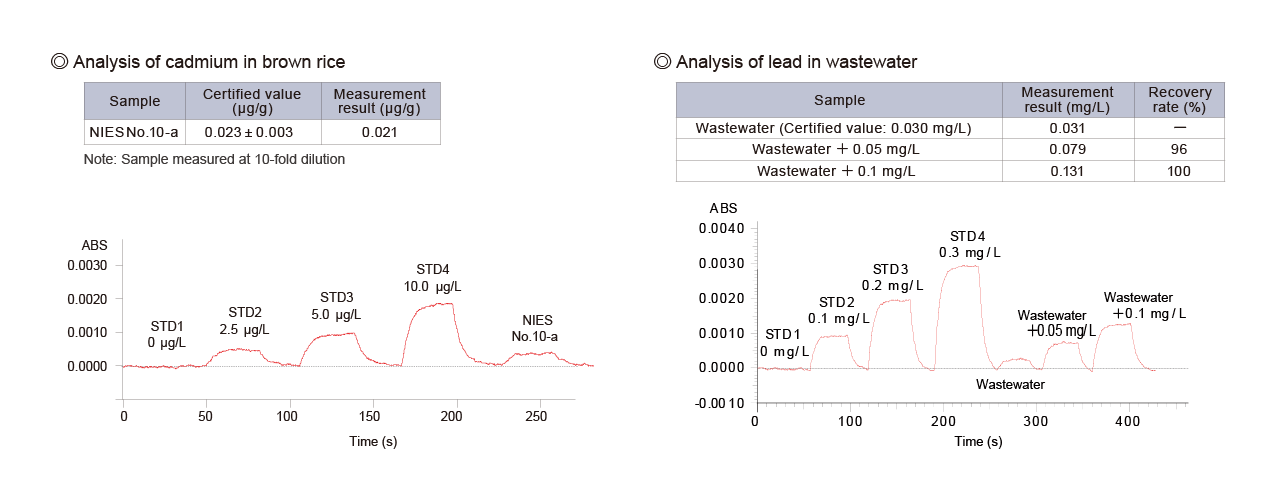

Analysis Examples

Flame Analysis

Achieving High-Sensitivity Analysis with Stable Baseline

A stable baseline is provided by the polarized Zeeman correction method, and low concentration analysis can be performed with high-sensitivity measurement without using any additional accessories.

Graphite Furnace Analysis

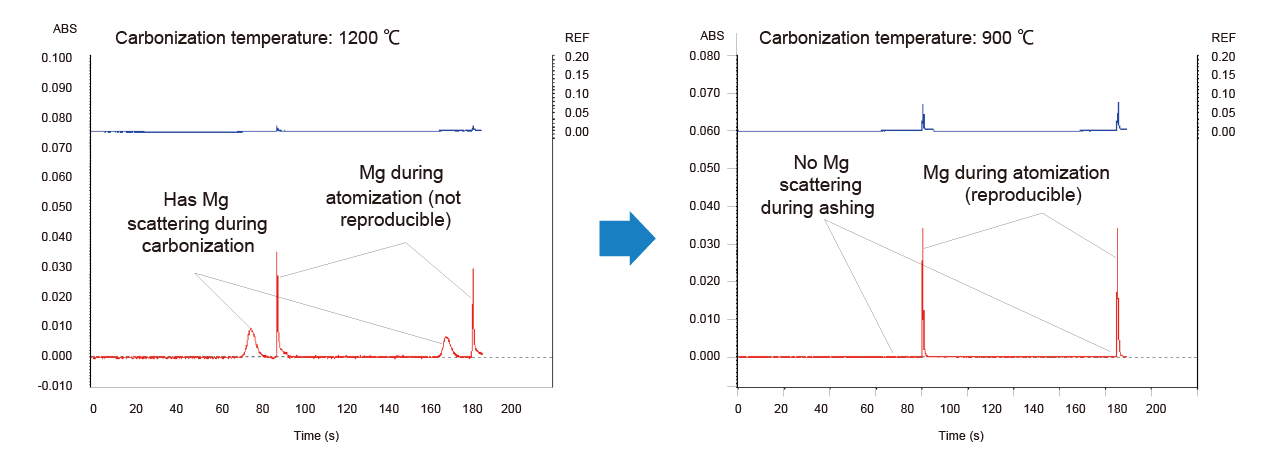

Batch Display of Atomizer Profiles

The absorbance and background signal are displayed as time elapses, making it possible to check for differences between samples at a glance. Regarding background measurement in particular, since background correction is applied even during the drying and ashing processes, the scattering of measurement elements can be monitored. The following diagram shows a profile confirming that magnesium is scattered at ashing temperature of 1200 °C. Scattering during ashing can be eliminated and absorbance with good reproducibility can be obtained by reducing the ashing temperature to 900 °C. Users who want to configure the parameter settings in more detail can also consider the setting values from the drying and ashing background signals.

Line up

| ZA4000 | ZA4800 | ZA4300 | ZA4700 | |

|---|---|---|---|---|

| Flame Analysis | ○ | ○ | ○ | |

| Rapid sequential Flame Analysis | ○ | |||

| Graphite Furnace Analysis | ○ | ○ |

* The polarized Zeeman correction is employed for all the analysis methods.

Introducing the measurement example using atomic absorption spectrophotometer.

The basics of atomic absorption spectrophotometers, from "Atomic absorption photometer," to "correction method of background (BKG)."