Training (Semiconductor Etch Equipment)

Training Programs

Hitachi High-Tech America has a state-of-the-art etch equipment training center in Hillsboro, Oregon. This center utilizes dedicated training etch systems and a staff of full-time, industry-experienced, certified instructors. A Hitachi instructor can also provide customized training at your location based on individual customer’s on-site training needs. Our competency-based curriculum is continually updated to meet changing customer and industry advancements and requirements, and is developed utilizing SEMATECH guidelines.

Hitachi offers its customers numerous different training courses, ranging from basic operation and maintenance skills, to advanced maintenance and troubleshooting of our Plasma Etch Systems.

Feel free to contact us with questions or to enroll.

Hitachi High-Tech America, Inc.

Etch Technical Training Center

3600 NE Huffman Rd.

Hillsboro, OR 97124

Email: HTA-SEDTechnicalTraining@hitachi-hightech.com

9000 Series Course Description

9000 Series Training Programs

These training courses are offered for many types of process chambers that are available for the 9000 series plasma etch platform.

Level 1: Basic System Operation and Minor Preventive Maintenance Web-Based Training

This web-based training curriculum introduces students to the overall system layout, configuration, theory, and basic operation of the 9000 system and the plasma etch process chamber.

-

Prerequisites:

None -

Ideal Experience:

At least 3 months in industry, 1 month with the 9000 Series Plasma Etcher.

Level 2: Advanced Preventive Maintenance and Expanded System Operation

Focus on performing scheduled preventive maintenance to the highest established level and an in-depth exposure to the system diagnostic checks.

-

Objective:

Upon completion the student will be able to perform preventive maintenance using the proper procedures while working on a team. In addition, written and performance-based evaluations will be used to determine comprehension level of the system operation software. -

Prerequisites:

Completion of Level 1 Web-Based Training -

Ideal Experience:

At least 6 months in industry, 2 additional months with the 9000 Series Plasma Etcher.

Level 3: Troubleshooting and System Calibration

This level of training will provide the student with an in-depth understanding of the sub-systems that control the 9000 Series Plasma Etch platform, understanding schematics, and basic troubleshooting procedures specific to the 9000. In addition, provide the necessary tools to perform system calibrations and alignments on the wafer transfer system.

-

Objectives:

Upon completion the student will be able to demonstrate, through performance, the proper procedures used to calibrate and align various sub-assemblies of the 9000 system. Understanding of the overall operation of the system will be evaluated by a troubleshooting test. Defective components will be introduced into the 9000, and the student will be required to identify the symptom, logically locate the problem, and repair or replace the defective component or condition. -

Prerequisites:

Completion of Level 2 9000 Training -

Ideal Experience:

At least 9 months in industry, 2 additional months with the 9000 Series Plasma Etcher.

9000 Series Advanced Courses

We offer multiple courses covering advanced 9000 Series systems. This level of training will provide the student with the necessary tools to perform scheduled and preventive maintenance on the wafer-handling systems, robots and major robot components and load port system alignment and component replacement. In addition, troubleshooting procedures specific to the 9000 systems will be introduced.

9000 Advanced Load Port course

-

Objectives:

Upon completion the student will be able to demonstrate, through performance, the proper procedures used to perform preventive maintenance, component replacement, calibrate the various sub-assemblies related to load ports and troubleshoot issues. Understanding of the overall operation of the system will be assessed by performance-based evaluations. -

Prerequisites:

Completion of Level 3 9000 Training -

Ideal experience:

At least 12 months in industry, 3 additional months with the 9000 Series Plasma Etcher.

9000 Advanced Robot course

-

Objectives:

Upon completion the student will be able to demonstrate, through performance, the proper procedures used to remove and replace the robot systems and sub-assemblies related to wafer handling and calibrate and align various sub-assemblies related to wafer handling on the 9000 equipment. Understanding of the overall operation of the system will be assessed by performance-based evaluations. -

Prerequisites:

Completion of Level 3 9000 Training -

Ideal experience:

At least 12 months in industry, 3 additional months with the 9000 Series Plasma Etcher.

Other advanced maintenance courses are available upon request. Feel free to contact us with questions or to enroll.

Legacy and 700 Series Course Description

Legacy and M700 Series Training Programs

Level 1: Basic System Operation and Minor Preventive Maintenance

Introduction to the overall system layout, configuration, basic operation and performance of low level preventive maintenance tasks.

-

Objectives:

Upon completion the student will be able to identify the major assemblies and sub-assemblies of the system, perform low-level preventive maintenance procedures (including wet cleaning of the etch chamber) and program and operate the necessary software programs for running wafers. Also, the student will be able to recognize and explain the system's basic normal operation sequence and indications and perform diagnostics to verify proper operations. -

Prerequisites:

None -

Ideal Experience:

At least 3 months in industry, 1 month with the Hitachi Plasma Etcher.

Level 2: Advanced Preventive Maintenance and Expanded System Operation

Focus on performing scheduled preventive maintenance to the highest established level and an in-depth exposure to the system diagnostic checks.

-

Objective:

Upon completion the student will be able to perform preventive maintenance using the proper procedures while working on a team. In addition, written and performance-based evaluations will be used to determine comprehension level of the system operation software. -

Prerequisites:

Completion of Level 1 Training -

Ideal Experience:

At least 6 months in industry, 2 additional months with the Hitachi Plasma Etcher.

Level 3: System Calibration and Troubleshooting

This level of training will provide the student with the necessary tools to perform system calibrations and alignments, including RF calibration and wafer transfer alignment. In addition, basic troubleshooting procedures specific to the Hitachi etch system will be introduced.

-

Objectives:

Upon completion the student will be able to demonstrate, through performance, the proper procedures used to calibrate and align various sub-assemblies of the etch system. Understanding of the overall operation of the system will be evaluated by a troubleshooting test. Defective components will be introduced into the equipment, and the student will be required to identify the symptom, logically locate the problem, and repair or replace the defective component or condition. -

Prerequisites:

Completion of Level 2 Training -

Ideal experience:

At least 9 months in industry, 2 additional months with the Hitachi Plasma Etcher.

M700 and Legacy Series Robotics

This level of training will provide the student with the necessary tools to perform scheduled preventive maintenance on the robots and wafer-handling systems, and advanced wafer-transfer alignment.

-

Objectives:

Upon completion the student will be able to demonstrate, through performance, the proper procedures used to calibrate and align various sub-assemblies related to wafer handling on the Hitachi etch equipment. These include calibration of the load ports, load locks, and the system robotics. Understanding of the overall operation of the system will be assessed by performance-based evaluations. -

Prerequisites:

Completion of Level 3 Training -

Ideal Experience:

At least 12 months in industry, 3 additional months with the Hitachi Plasma Etcher. -

Other Hitachi Legacy Equipment:

Other Hitachi legacy plasma etch systems training for equipment prior to the current 9000 series equipment is available on a limited basis. -

Location:

All legacy equipment training will be taught at your facility, on your equipment. Please contact us for a quote and details.

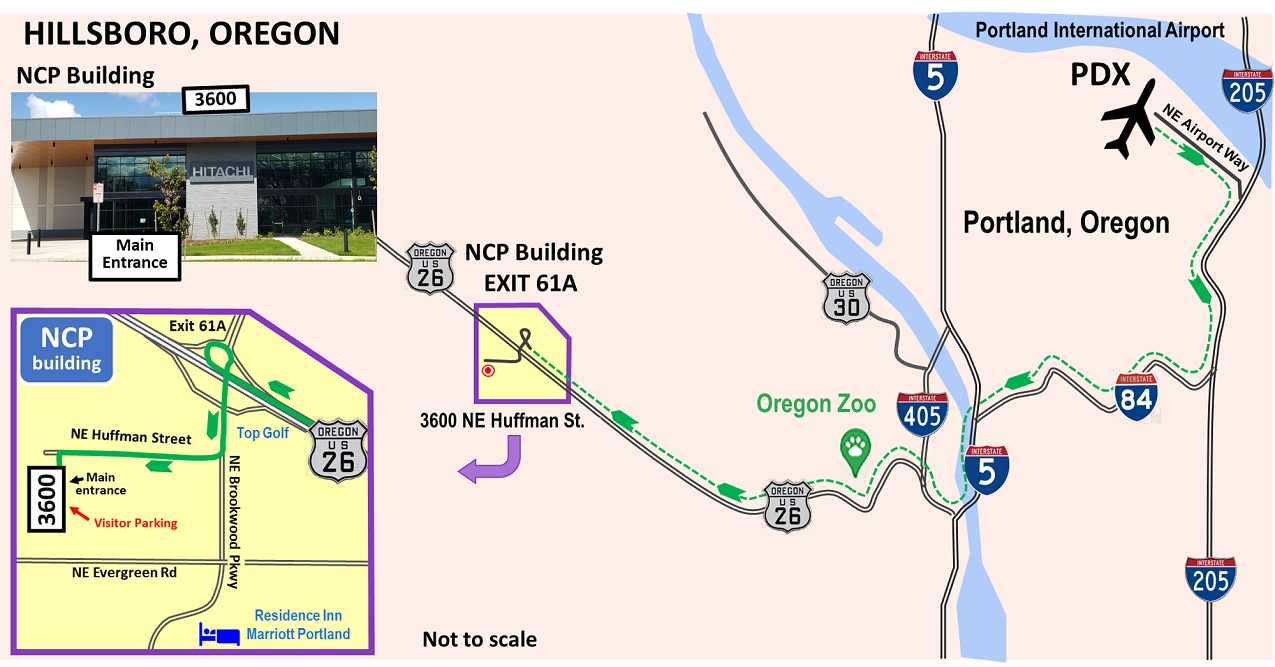

Training Center Location

Hillsboro, Oregon

The Hitachi Etch Equipment Training Center is located in Hillsboro, Oregon, at Hitachi’s Nanotechnology Innovation Center Portland (NCP).

NCP Building, Hillsboro, Oregon

Directions from PDX Airport:

- From PDX Airport, take NE Airport Way to Freeway I-205 South.

- Take Exit 21B to merge onto I-84 W / US-30 W to I-5 South toward Salem.

- Take the I-405 / US-26 Exit on the left toward Beaverton.

- Take Exit 1D and merge onto US Hwy 26 West.

- Take Exit 61A for NE Brookwood Pkwy South.

- Turn right on NE Huffman Street.

- The Hitachi facility is on the left at 3600 NE Huffman Drive near the end of the road.