Health and Safety Programs

Basic Approach

The Hitachi High-Tech Group is committed to maintaining and improving health and safety management standards, such as the enhancement of health management and prevention of work-related accidents for all employees (including employees of other organizations who perform work under the management of business sites, contractors, and others) involved in all business activities at all business sites and in all business organizations that make up those business sites based on the Hitachi Group's health and safety policy, Health and Safety Always Comes First, with the formula S (Safety) >> Q (Quality) > D (Delivery) > C (Cost). With regard to measures against large-scale disasters, we regularly identify risks in the same manner as workplace safety patrols and business site safety inspections and take advance measures to minimize damage.

The Hitachi Group Health and Safety Policy (excerpt)

- Principle

"Health and Safety Comes First." - Policies

In accordance with our mission, "Contribute to society through the development of superior, original technology and products," and as a global corporate group whose business is based on close partnerships with society, the Hitachi Group will endeavor to ensure safe and healthy workplaces under the principle of "Health and Safety Always Comes First" in all of our business activities.

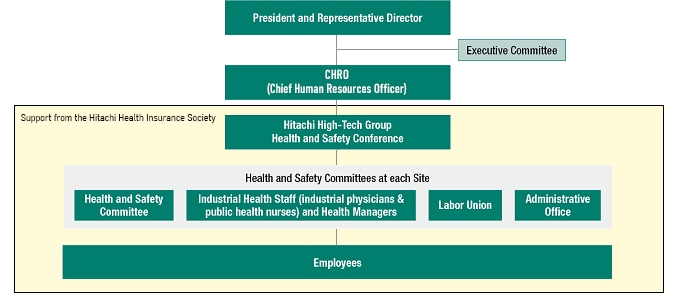

Organization

At Hitachi High-Tech, the status and results of activities relating to health and safety including those at Group companies are periodically reported to the Board of Directors, and information on management conditions is shared.

The officer responsible for health and safety management makes proposals on matters to be undertaken throughout the Group and matters that require an immediate response, and Group-wide health and safety measures are undertaken throughout the Group with the approval of management.

Safety Initiatives

At Hitachi High-Tech, we hold a Group Health and Safety Conference each half-year for the people responsible for the promotion of health and safety in the workplace, led by the officer responsible for health and safety (CHRO*/CRO* , Vice President and Executive Officer Takeshi Iizuka), so that we can improve health and safety activities and the level of health and safety throughout the Group. The officer responsible for health and safety acts as the chair of the conference. If it is determined that there have been any major accidents or that there are notable issues with safety management, the workplace in question will be designated as a priority safety management workplace, and we will ensure that reforms are implemented swiftly, in accordance with the standards related to the priority safety management designation system. We also investigate and deliberate on matters relating to disaster prevention and health management at each workplace, and to make improvements, the Hitachi High-Tech health and safety committee actively conducts measures including risk assessments and the implementation of intrinsic safety* in production equipment, primarily at our manufacturing sites. By operating the Hitachi Health and Safety Management System, which is compliant with ISO 45001, we undertake voluntary and systematic measures that cover all persons who work under our organizational management or engage in activities relating to work (including the employees of cooperating companies, contractors, and temporary workers).

* CHRO: Chief Human Resources Officer

* CRO: Chief Risk management Officer

* Intrinsic safety: The elimination or reduction of any elements and factors that can pose a hazard to safety.

Health and Safety Committee

The Health and Safety Committee at each site consists of employees with experience in health and safety such as safety and health managers, representatives of trade unions, and industrial physicians. It discusses minimization of safety risks based on deliberations on establishment and revision of health and safety regulations and standards as well as on employees’ opinions.

In addition, we carry out safety-inspection patrols and have safety diagnosis and safety presentations conducted by external experts at our manufacturing sites in an effort to further strengthen our safety management initiatives through employee participation.

Performance Data

Occurrence of Occupational Accidents: Targets and Achievements

Hitachi High-Tech along with Group companies undertakes various safety measures with a target of zero occupational accidents. In FY2023, although the total number of accidents across the Group was 11 (including one which was accompanied by lost worktime), a decrease from 12 accidents in FY2022 (none of which were accompanied by lost worktime), there was an occurrence of an accident accompanied by lost worktime. In addition to taking measures intended to prevent accidents, we implement a cross-department approval that includes comply with and requiring compliance with set rules, creating mechanisms and conducting education that allows each individual including subcontractors to act with an awareness of safety. Furthermore, we will continue to reinforce measures and implement thorough safety management to raise safety awareness and completely eliminate occupational accidents by fostering a health and safety culture and climate and sharing best practices through safety inspections at manufacturing sites, which was launched in FY2019.

Occurrences of Occupational Accidents

(Occurrences)

| Year | 2019 | 2020 | 2021 | 2022 | 2023 | |

|---|---|---|---|---|---|---|

| Lost-time incidents (Number of fatalities) | Hitachi High-Tech Group | 2(0) | 3(0) | 2(0) | 0(0) | 1(0) |

| Accidents not accompanied by time off work | Hitachi High-Tech Group | 11 | 5 | 8 | 12 | 10 |

| Total | Hitachi High-Tech Group | 13 | 8 | 10 | 12 | 11 |

| Number of hours worked | Hitachi High-Tech Group | 16.65 million hours | 17.42 million hours | 18.00 million hours | 19.42 million hours | 20.23 million hours |

(Scope: consolidated Group companies in Japan)

Lost-time Incident Rate

* Accident rate calculated as number of occupational deaths and injuries/gross hours worked × 1,000,000

Initiatives

Revitalizing Group-wide Health and Safety Activities

To improve the standard of health and safety activities throughout the Group, we have established the High-Tech Group Health and Safety Liaison Committee. This committee helps to revitalize Group-wide health and safety activities through presentations introducing examples of health and safety initiatives at each Group company, and the exchange of opinions on measures to address common Group-wide issues.

Disaster Risk Reduction Activities

As with our safety activities, we proactively undertake Group-wide disaster risk reduction activities. During regular evacuation drills, we confirm the safety of employees who come to work and those who work at home, and we also conduct regular drills to confirm the locations of fire hydrants and fire extinguishers and how to use them. In addition, we are working to raise awareness of disaster preparedness and establish systems that will enable employees to act autonomously in the event of a disaster.

We have also set up in-house fire brigades at each manufacturing base. These conduct regular firefighting drills to ensure that they are prepared for any unforeseen situations.

Implementation of Occupational Health and Safety Training

To prevent occupational accidents, the Group has the Health and Safety Committee members at each workplace convey communications to, and educate all employees on occupational health and safety issues a regular basis.. In particular, we conduct safety-focused training at each organizational level, as well as education and drills tailored to each organization and business type, for line managers and safety staff and for workers engaged in specific hazardous activities in the field. In addition, we provide individual guidance to new hires and temporary workers who may be unused to the work or environment, as they are at a higher risk of injury. We perform this education and training through on-the-job training after education and training to increase awareness and understanding of work procedures and dangers before engaging in work

Occupational Health Activities

Mental health workshop

We are implementing health promotion measures and enhancing health education among our employees. Initiatives in this area include efforts to reduce overtime hours, encourage employees to take advantage of special health check-ups and other medical examinations, and improve awareness of health management through education focused on this subject. In addition, we believe that enhancing mental health care for employees is an important task for the Group. We are regularly conducting mental health education for "line care" (routine support provided by line managers) and training on how to cope with stress (understanding your own stress and dealing with it appropriately) with a view toward strengthening self-care. We are also developing initiatives throughout the Group, including the expansion of counseling services in partnership with external EAP bodies and the offering of referrals to specialist physicians.

Implementation of Health Examinations

All Group employees in Japan are members of the Hitachi Health Insurance Society.

In addition, periodic health examinations are conducted once a year, and we appropriately manage the health examinations by recommending employees to take the examinations. Additionally, for employees age 35 and older, we recommend and promote comprehensive medical examinations that include statutory health examinations, as well as screenings for specific body parts according to their age, to aid in the early detection and treatment of lifestyle diseases and cancers.

Efforts Toward Health and Productivity Management

Declaration of Health and Productivity Management

Based on the Hitachi Group's basic philosophy that Health and Safety Always Comes First, we are engaged in health and productivity management activities to maintain and promote the health of our employees. We view employee health as a management issue, and aim for further corporate growth by improving productivity and organizational strength through efforts to maintain and promote employee health.

Health and Productivity Management Structure

Our Health Challenges and Initiatives

Based on our vision of improving employee wellbeing and corporate value, we believe it is important for each and every employee to recognize the importance of mental and physical health, and to improve their health literacy and practice healthy behaviors.

In order to achieve this, we have set KPIs for “increasing the percentage of employees undergoing specific health guidance” and, because the percentage of employees with mental illness who took time off from work has been increasing yearly, “reducing the percentage of employees with mental illness who took time off from work.” We are taking the following initiatives to address these challenges.

Initiatives

- Mental health measures (care for high-stress individuals through stress checks, promotion of measures to improve the workplace environment through stress check results briefings and training for line managers, interviews with industrial physicians for employees who work long hours, establishment of internal and external hotlines, implementation of seminars on mental health measures, etc.)

- Measures to prevent lifestyle-related diseases and improve health (collaborative health care with health insurance societies, establishment of health consultation hotlines, promotion of specific health checkups and specific health guidance, implementation of walking events, and smoking cessation programs)

- Measures to promote workstyle improvement (promotion of annual paid leave use [setting recommended annual leave days] and annual leave use targets, promotion of time efficiency through use of flextime, and promotion of work-life balance through use of teleworking systems)

Recognized as one of the 2024 Health & Productivity Management Outstanding Organizations (Large Enterprise Category)

Hitachi High-Tech was recognized as a 2024 Health & Productivity Management Outstanding Organization in the large enterprise category under a program administered by the Ministry of Economy, Trade and Industry and Nippon Kenko Kaigi. This is the seventh consecutive year that the company has received this certification, and this year, seven other Group companies in Japan received certification for a total of eight companies throughout the Group.

In addition, we actively used telework systems including working from home, strictly enforce no overtime days, curtail work-related email at night and on days off, encourage employees to take paid leave, and implement other workstyle reforms to enhance employees’ work-life balance so that we can create environments where employees can work comfortably and achieve well-balanced methods of work.

The Hitachi High-Tech Group thoroughly implements the formula S (Safety) >> Q (Quality) > D (Delivery) > C (Cost), introduced a health and safety management systems (compliant with ISO 45001) that places the highest priority on workplace safety and maintaining and enhancing the health of each employee, and focuses efforts on mitigating the risks in high-risk work and preventing accidents. With regard to health management, we are implementing measures to reduce the percentage of employees experiencing high levels of stress to less than 10% through a stress check program and strive to prevent illness and improve lifestyle habits by increasing the implementation rate of specific health guidance (the target implementation rate is at least 55%).

* Health-based management: Strategic practices that consider the health management of employees and other from a business management perspective.

* Health-based management is a registered trademark of Nonprofit Organization Kenkokeiei.

Trends in Health-Related Indicators

| Performance Indicator | Scope | FY2022 Results | FY2023 Results | FY2024 Targets | |

|---|---|---|---|---|---|

| Physical | Percentage of employees undergoing regular health checkups | Non-consolidated | 100% | 100% | 100% |

| Percentage of employees undergoing regular health checkups | Consolidated*3 | 100% | 100% | 100% | |

| Percentage of employees undergoing specific health checkups | Non-consolidated | 96.7% | 96.6% | 97.8% | |

| Percentage of employees undergoing specific health guidance | Non-consolidated | 43.6% | - | Over 55% (FY2023 target) |

|

| Percentage of employees maintaining a healthy weight (BMI between 18.5 and 25) |

Non-consolidated | 63.4% | 64.0% | - | |

| Percentage of employees who have metabolic syndrome or are predisposed to have metabolic syndrome | Non-consolidated | 26.7% | 27.2% | - | |

| Percentage of high-risk individuals | Non-consolidated | 8.9% | 8.7% | - | |

| Percentage of smokers | Non-consolidated | 23.3% | 21.5% | - | |

| Percentage of employees with adequate sleep | Non-consolidated | 71.4% | 69.4% | - | |

| Mental | Percentage of employees undergoing stress checks | Non-consolidated | 88.8% | 89.3% | - |

| Percentage of employees who took the stress check and were highly stressed | Non-consolidated | 11.0% | 11.1% | Less than 10% | |

| Percentage of employees with mental illness*1 who took time off from work | Non-consolidated | 0.66% | 0.78% | Less than 0.70% | |

| - | Percentage of positive engagement responses*2 | Non-consolidated | 68.8% | 68.7% | 62.7% (Hitachi Group KPI) |

*1. Number of employees who were absent from work for more than seven consecutive days due to non-occupational injury or illness divided by the annual average of all employees

*2. Average of all employees who gave a positive response rate (4 or 5 out of 5) on the engagement index (e.g., feeling a sense of fulfillment and achievement in one's own work) based on Hitachi Group's original questions

*3. Consolidated Group companies in Japan

Implementation Status of Health and Safety Training and Education

FY2023

| Disaster risk reduction | Disaster response drills Safety confirmation response training using the safety confirmation system |

|---|---|

| Develop and health and safety culture (leadership, roles, responsibility) | Specialized safety training for managers Specialized safety training for safety managers |

| Mental health training sessions | Line care training Self-care training Resilience training Training for human resource and health personnel Training on psychological safety |

Evaluation of Health & Safety Risks

The company, including Group companies, aims to reduce employee health and safety risks by conducting periodic (once a year) risk assessments with regard to work methods, and handling of machinery and chemicals during assembly, production, etc., mainly at manufacturing sites. We also conducted prior identification of risks and dangers and assessments (estimations) of risks relating to new installation and improvement of equipment, and changes in chemical substance handling (including work safety and reduction of environmental impact) in accordance with various laws, regulations and guidelines. We established work procedure manuals for safe work, loaned protective equipment for the purpose of preventing work-related accidents and ensuring employee safety, and linked them to risk reduction measures including work training.

In addition, we encourage individuals who work under our organizations to report accidents, sources of danger, risks, and opportunities and we take measures to ensure that those who make reports do not experience any disadvantage.

To further improve health and safety activities and the standard of management throughout the Group, experts in electronics, mechanics, chemistry, heavy equipment handling, and other areas patrol each site and evaluate the risk of accident occurrence. In addition, they will seek to improve health and safety management throughout the Group by developing and sharing good practices and examples of necessary improvements at each workplace across the Group. In FY2023, we will conduct safety patrols and disaster risk assessments at overseas bases (three companies in China). We seek to raise health and safety levels at other overseas sites on a global scale.

Periodic Risk Assessment

| Scope | Unit | 2023 | |

|---|---|---|---|

| Occupational health and safety risk assessment implementation rate (By business entity) |

Consolidated |

% | 100% |